3D printing has earned a great deal of attention as a new, innovative and futuristic form of technology, but it also has a real practical use that makes it more than a mere fad. It’s thought that the sector will be worth $21 billion by 2020 – which would mark a seven-fold growth in just seven years from 2013.

The mainstream appeal is showing little sign of easing off. While the initial rush of excitement may be over, developments such as London’s new 3D printing restaurant – where everything from the food to the furniture and utensils is printed – will continue to capture the imagination and take this to the next level.

Yet businesses that want to harness the potential of 3D printing need to make sure they use it wisely. The technology has been available to big businesses for a long while, but the fresh interest – and new applications – are leading more and more firms to consider this as a way of vastly cutting down production time and costs.

The industries where 3D printing is already having an impact

Tech Republic has highlighted many of the businesses that are already putting 3D printing to good use in a number of different ways.

It shows how car manufacturers such as Ford have actually been using this for years to generate parts for their production line and how toy and game maker Hasbro and confectioner Hershey’s are also able to join the 3D revolution to produce new products in new ways.

Whole cars, office buildings and miniature tools have also all been created to show the breadth of uses this technology can have. The sky is the limit.

Surface preparation and finishing

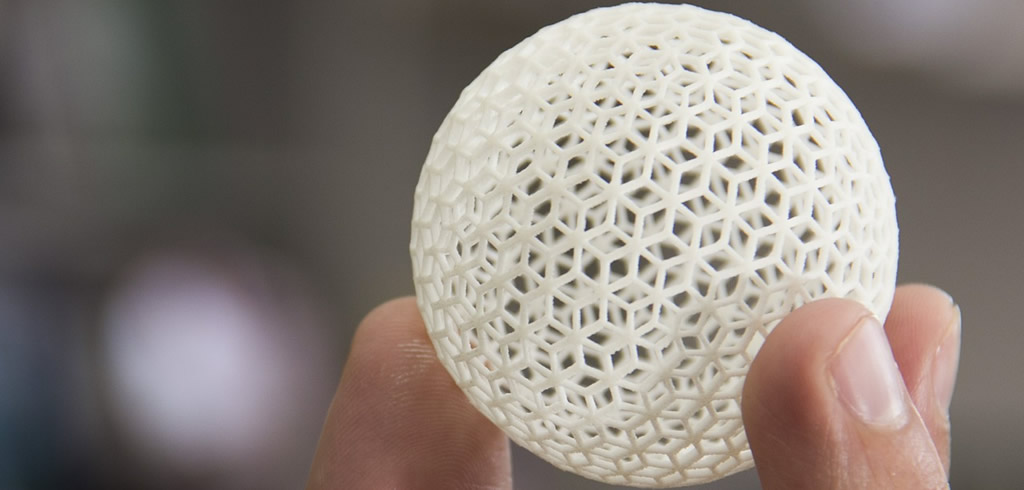

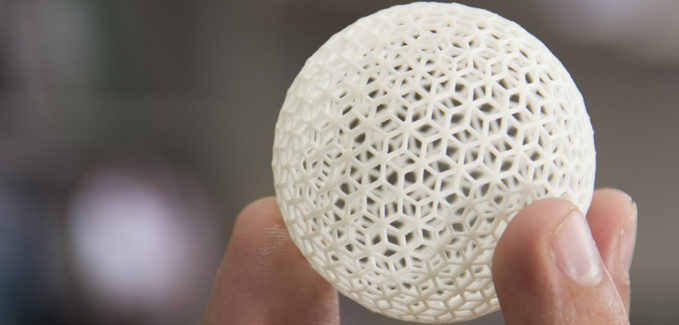

The important thing to bear in mind, however, is that 3D printing does not necessarily produce the finished article. It can create products, but not necessarily finished products.

Components, parts or models produced in this way need to be ‘finished’ and it’s this process that a business must take into consideration when weighing up how it will be able to capitalise on 3D printing.

Painting a product up so that it ‘looks the part’ is important and can be tricky if not done properly. Businesses need to realise that this involves preparing, painting and finishing a surface to give a final, professional look that allows a part to be used in a meaningful context.

The sorts of blast cabinets offered by firms such as Airblast are able to handle the surface preparation tasks you’ll need before you select and apply the appropriate final layer.

Fictiv has produced a guide that shows, from start to finish, the work involved in doing this with a simple product – an Apple Watch stand. This is a useful read for businesses that want to consider how to finish off 3D printed products and demonstrates the ways in which different finishes can create a very different look for identical products.

This final phase is crucial. Without the right finish 3D printing will only take your business so far. Plan how to finish off your products – with the right equipment and materials – and you’ll get the most from the new technology available to you.

Photograph by metalurgiamontemar0